Latest News

-

May 23, 2025

Industrial Refrigeration Training That Prepares You Right

A Comprehensive 5-Day Course for Safety, Skills, and Certification

Industrial Refrigeration Technical College (IRTC) recently delivered another successful session of its 5-day Industrial Refrigeration Training in Introduction to Ammonia Refrigeration and HAZWOPER Combo Course. The thorough class is a powerful blend of theory, safety compliance, and real-world application. Moreover, the content at IRTC is overall better absorbed. This is because IRTC's instructors aren’t just teachers—they’re actively engaged engineers with real-world design/build experience. Students aren’t just learning the material; they’re gaining practical insights from professionals who do this work every day.

This course is tailor-made for entry-level refrigeration operators, PSM/RMP personnel, and emergency responders who work with ammonia systems. By combining Ammonia Refrigeration fundamentals with HAZWOPER Hazardous Material Technician Training, participants gain both a solid technical foundation and the emergency response skills critical in today's industrial environments.

What Students Learn in the Ammonia Refrigeration & HAZWOPER Combo Course

Participants spent the week diving into:

• Refrigeration system fundamentals

• Process Safety Management (PSM) and Risk Management Planning (RMP)

• Hazardous materials response techniques

• Regulatory compliance and safety protocols

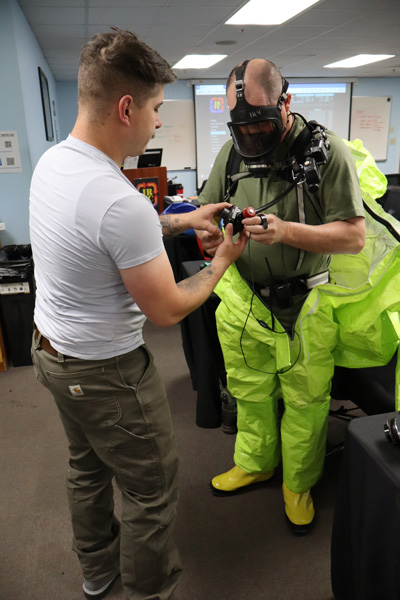

But this isn’t just book learning. Students also completed hands-on training in a fully operational ammonia refrigeration facility, with real-time scenarios that required focus, coordination, and fast thinking.

Real-World Crisis Simulations: Training That Sticks

One of the standout components of this industrial refrigeration training is the practical ammonia leak response simulation. During these drills, students had to:

• Communicate effectively under pressure

• Execute technical procedures safely

• Work as a cohesive team in dynamic, high-stakes scenarios

The class did a fantastic job. Their ability to apply what they’d learned in a high-intensity environment demonstrated not only technical skill, but also leadership, communication, and decision-making under pressure.

Time to Unwind: IRTC Visits Hazy Mountain

After an intense week of training, the IRTC team was invited to Hazy Mountain Vineyards & Brewery. This top-notch spirit crafting jewel has a stunning location nestled in the Blue Ridge Mountains. It was the perfect spot to unwind, reflect, and celebrate the teams accomplishments.

The breathtaking views, great conversation, and relaxed atmosphere offered a well-deserved break for everyone involved. It was a reminder that while safety and skill are serious business, building camaraderie and taking time to recharge are just as important in the development of top-tier professionals.

Learn more about the venue at hazy-mountain.com.

Certification and Professional Development Hours (PDH)

Upon successful completion of the course, quizzes drills and all, each student received a certificate of completion and earned 24 Professional Development Hours (PDH).

This certification validates their preparedness to operate in ammonia systems and respond to hazardous material incidents, setting them up for career advancement and field readiness.

Why Choose IRTC for Industrial Refrigeration Training?

IRTC’s approach to industrial refrigeration training is immersive, practical, and aligned with real industry needs. As one of the few programs uniquely specialized in both CO₂ and ammonia refrigeration, IRTC equips students with hands-on knowledge that’s directly tied to today’s most effective, sustainable, and critical industrial cooling systems. Our instructors actively design and build these systems, ensuring the training is as practical as it is relevant.

Ready to get certified and build field-ready confidence?

If you’re looking to train your team, or yourself, in both the general mechanics of refrigeration and the critical safety practices around ammonia, this combo course delivers for sure.

Check out our upcoming class dates HERE and register now

-

December 13, 2024

Level Up Your Skills: IRTC’s Operator 2 Ammonia Refrigeration Course

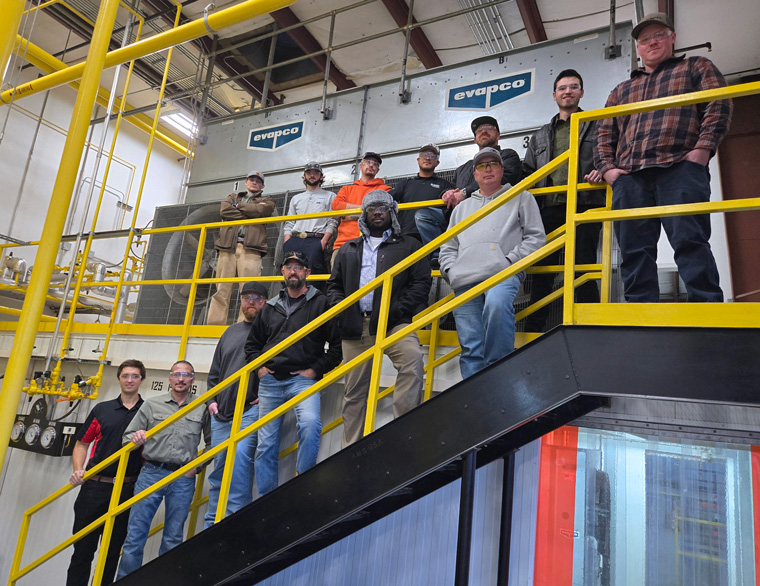

The Industrial Refrigeration Technical College (IRTC) hosted its highly sought-after Operator II course this week. This Industrial Refrigeration Operator 2 is tailored for professionals eager to enhance their expertise in ammonia refrigeration systems. Our advanced program builds on foundational skills, focusing on troubleshooting, system optimization, and CIRO exam preparation. Graduates earn a certificate, along with 36 PDH credits, solidifying their professional credentials.

The Industrial Refrigeration Technical College (IRTC) hosted its highly sought-after Operator II course this week. This Industrial Refrigeration Operator 2 is tailored for professionals eager to enhance their expertise in ammonia refrigeration systems. Our advanced program builds on foundational skills, focusing on troubleshooting, system optimization, and CIRO exam preparation. Graduates earn a certificate, along with 36 PDH credits, solidifying their professional credentials.

In just 4.5 days, attendees gain critical knowledge. Key topics include hot gas defrosting techniques, efficient system maintenance, and the operation of evaporators, vessels, and pumps. Active learning is emphasized, with hands-on training using IRTC's fully operational ammonia system. The RETA Industrial Refrigeration 2 book, a vital resource for the CIRO exam, is provided.

Transitioning from theory to practice, students tour IRTC’s state-of-the-art lab and shop. This unique feature enables them to connect technical concepts to real-world applications. Meanwhile, experienced instructors such as our very own mechanical engineer, Ryan Barolo (pictured on far left), guide participants through every step, ensuring comprehension and readiness to excel.

This course, and others are hosted at IRTC’s Lyndhurst, VA campus. Seats are limited, so early registration is encouraged. We also offer online industrial refrigeration training courses!Ready to advance your career? Contact us for more details and to secure your spot in one of our many upcoming 2025 industrial refrigeration classes today. Don’t miss this opportunity to elevate your skills and confidence in ammonia refrigeration.

-

December 9, 2024

Thank you Operator I participants

What better start to December than for IRTC to ring in an Operator I class! Our knowledgeable instructor, Erich Demaree, helped students gain a deep understanding of key refrigeration components like compressors, condensers, evaporators, and expansion devices. These individuals came together to develop a comprehensive familiarity of how these elements work together to drive system performance, efficiency, and reliability, providing a solid foundation for operators looking to excel in ammonia refrigeration.

What better start to December than for IRTC to ring in an Operator I class! Our knowledgeable instructor, Erich Demaree, helped students gain a deep understanding of key refrigeration components like compressors, condensers, evaporators, and expansion devices. These individuals came together to develop a comprehensive familiarity of how these elements work together to drive system performance, efficiency, and reliability, providing a solid foundation for operators looking to excel in ammonia refrigeration.Thank you to everyone who joined us and committed to mastering the fundamentals of ammonia refrigeration—your dedication sets the standard for safety and expertise in the industry!

Contact the Industrial Refrigeration Technical College today to enroll in one of our upcoming in-person or online courses!

-

November 15, 2024

Another Operator 1 class in the books!

We’re proud to announce the successful completion of another Operator 1 Course at our premium ammonia training facility here at IRTC! This program is a cornerstone for those entering the field of ammonia refrigeration, equipping participants with the knowledge and hands-on skills needed to safely and effectively operate ammonia systems.

Our graduates spent the week diving deep into topics like:

✅ The fundamentals of ammonia refrigeration systems

✅ Best practices for system operation and maintenance

✅ Key safety protocols to ensure smooth and secure operationsBy completing this training program, these individuals are now better prepared to handle the challenges of industrial refrigeration while promoting safety and efficiency in their workplaces.

Why Choose IRTC for Your Ammonia Refrigeration Training?

Whether you’re new to the industry or looking to enhance your skillset, IRTC is the leading destination for ammonia operator training, ammonia safety training, and industrial refrigeration courses. Our expert instructors and hands-on approach ensure you gain the practical knowledge and confidence you need to succeed.

Ready to invest in your career? Explore our upcoming in-person courses, OR online courses, and join the growing community of refrigeration professionals taking their expertise to the next level.